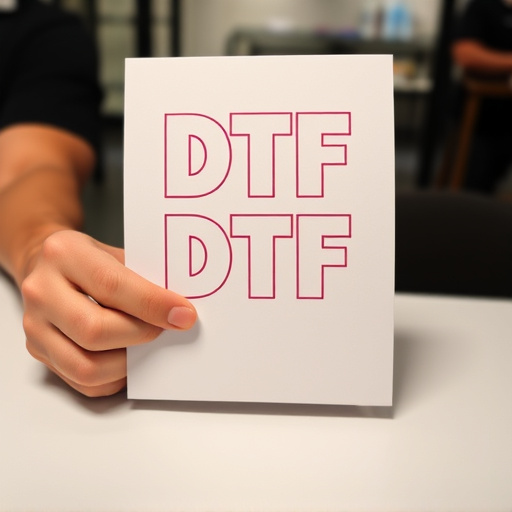

Direct-to-film (DTF) transfer printing is a modern method allowing users to directly print intricate designs onto various materials using liquid ink. Beginners should prepare digital designs at high resolution for compatibility with DTF printers and inks. DTF offers vast creative potential, enabling the production of personalized items like jewelry and home decor. Choosing the right transfer paper and solvent-based inks ensures high-quality prints. The simple four-step process involves preparing an image, applying adhesive, positioning it on a sheet, peeling it off, and pressing onto a substrate. DTF technology empowers hobbyists to create unique, detailed designs on ceramics, wood, fabric, and metal.

Discover the exciting world of Direct-to-Film (DTF) transfer technology—a game-changing method for hobbyists and artisans looking to bring their creative visions to life. This beginner’s guide explores the benefits of DTF, from its ease of use to the vast array of materials it can print on. We’ll walk you through the process, from choosing the right materials to creating your first DTF prints, unlocking endless possibilities for custom designs and unique art pieces.

- Understanding Direct-to-Film (DTF) Transfer: A Beginner's Guide

- Benefits of DTF for Hobbyists and Artisans

- Choosing the Right Materials for DTF Printing

- Step-by-Step Process: Creating Your First DTF Print

- Creative Applications of DTF Technology

- Top Tips for Successful DTF Transfers and Prints

Understanding Direct-to-Film (DTF) Transfer: A Beginner's Guide

Direct-to-film (DTF) transfer is a cutting-edge technique that allows hobbyists and artisans to print intricate designs directly onto various materials, like wood, fabric, or metal. Unlike traditional methods that require multiple steps for preparation and application, DTF simplifies the process. It involves using specialized printing technology to apply designs directly from digital files onto the desired surface through a liquid ink process.

For beginners, understanding the DTF transfer process starts with preparing your design digitally. The image should be high-resolution and optimized for the material you intend to print on. Next, select the appropriate DTF printer and ink compatible with your project. Once set up, the printer will precisely deposit the ink onto the surface, creating detailed prints that can range from simple graphics to complex, multi-colored artwork. This method is ideal for those seeking a creative outlet, as it offers endless possibilities for personalization and unique design expression.

Benefits of DTF for Hobbyists and Artisans

Direct-to-film (DTF) technologies offer a host of benefits for hobbyists and artisans looking to create unique, high-quality designs. One of the key advantages is its ease of use; DTF Transfer allows creators to bypass complex setup processes often associated with traditional printing methods. This user-friendly approach means that anyone, regardless of technical skill, can produce intricate and detailed prints with ease.

Additionally, DTF Printing provides a versatile platform for artistic expression. It enables the direct application of designs onto various surfaces, opening up a world of possibilities for personalized crafting projects. Whether it’s custom-made jewelry, tailored home decor items, or one-of-a-kind art pieces, DTF Prints offer an efficient and cost-effective solution for bringing creative visions to life.

Choosing the Right Materials for DTF Printing

When embarking on a direct-to-film (DTF) printing project, selecting the appropriate materials is paramount to achieving high-quality DTF prints. The right choice ensures vibrant colours, crisp details, and long-lasting durability. Consider using premium transfer paper designed specifically for DTF printing, as it offers superior adhesion and can withstand various fabric types. Look for papers with a smooth finish that allows ink to adhere evenly, resulting in fine lines and precise images.

Additionally, the type of ink used is critical. Solvent-based inks are popular choices due to their ability to produce rich, vibrant DTF prints. These inks also dry quickly, making them ideal for efficient production runs. Ensure the ink is compatible with your printer and capable of creating fine details. Testing different inks and papers can help you find the perfect combination for your specific DTF transfer needs, enabling you to create stunning artwork on a variety of surfaces.

Step-by-Step Process: Creating Your First DTF Print

Creating your first Direct-to-Film (DTF) print is a straightforward process that can be completed with just a few simple steps. First, design or source an image that you want to transfer onto your chosen material. This could be artwork, text, or even photos, and it should be printed at the appropriate resolution for best results. Next, prepare your DTF transfer sheet by ensuring it’s clean and free of any debris. Apply a thin layer of pressure-sensitive adhesive to the sheet, following the manufacturer’s instructions for coverage and drying time.

Now, carefully place your designed image onto the adhesive side of the transfer sheet, aligning it precisely. Use a smooth, flat surface to press down gently, ensuring full contact between the design and the transfer sheet. Allow the adhesive to cure according to the product guidelines. Once cured, carefully peel back the transfer sheet, revealing your DTF print ready for application to your desired substrate—be it wood, fabric, or even ceramics—using a heat press or iron, following the recommended temperature and pressing instructions for optimal adhesion.

Creative Applications of DTF Technology

Direct-to-film (DTF) technology offers a world of creative possibilities for hobbyists and artisans looking to bring their designs to life. One of its most appealing applications is in transferring intricate patterns and images onto various surfaces, from ceramics and wood to fabric and metal. This process allows crafters to create custom, one-of-a-kind pieces with ease. For instance, a hobbyist potter can use DTF to apply complex designs featuring floral motifs or abstract art directly onto their pottery, achieving a professional finish without the need for complicated carving or painting techniques.

DTF Printing is particularly versatile in the realm of textiles and apparel. Artisans can easily print unique patterns on t-shirts, totes, or scarves, offering customers customizable, personalized items. The technology’s precision and detail ensure that intricate designs with fine lines and subtle color gradients are reproduced accurately. This makes DTF ideal for creating artistic garments, accessories, or home decor items that stand out in the market due to their exceptional visual appeal.

Top Tips for Successful DTF Transfers and Prints

Direct-to-film (DTF) transfers and prints offer a fantastic way for hobbyists and artisans to bring their creative visions to life. Here are some top tips to ensure your DTF experience is a success:

First, prepare your design digitally, ensuring it’s high-resolution and optimized for the medium you plan to use. Use compatible software to create or edit your artwork, keeping in mind that precision and detail are key. Next, select the right DTF film for your project; different materials suit various applications, from fabric to wood and more. Properly apply the film to your substrate, ensuring it’s centered and secure to avoid bubbles or misalignments. Consider using a heat press or iron for a smooth, crisp finish.